Sparks Will Fly - Electrostatic Discharge Solutions

Share

Static electricity is a familiar occurrence in everyday life, both in and out of the workplace. Electrostatic discharge occurs when two electrically charged objects touch or come into close contact. I’m sure at one point almost all of us have tested the effects of static electricity by rubbing a balloon against our hair, or a sweater, and then sticking it to a wall for fun. While its quite common to experience the odd tingly little shock many ESD events can create a visible spark, cause more serious discomfort, equipment damage or potentially a fire or an explosion. With more electrical equipment than ever in the workplace, it’s essential to consider Electrostatic discharge in terms of Health & Safety for your workforce, visitors and the general public.

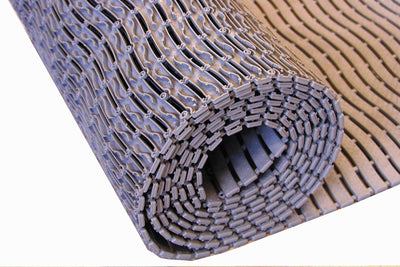

Thankfully there is a good range of Electrostatic Discharge Solutions available on the market, helping to reduce or eliminate static build up and therefore minimising the risk of a serious static discharge event. Many maintenance and H&S managers consider ESD matting and flooring as the most effective way to prevent ESD becoming a problem. Static dissipative matting ensures charges flow to ground more slowly, while conductive matting will drain static even faster.

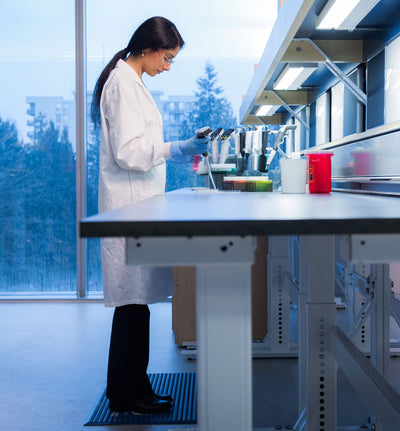

The right ESD matting will drain static electricity while also safeguarding workers and equipment. ESD matting is ideal for use across a huge range of industries, from switchboards, to manufacturing plants, engine and operations rooms, gyms and production lines.

If you are concerned about electrostatic discharge please don’t hesitate to contact us about ESD matting, as we would be delighted to suggestion possible solutions for your particular application.